How To Make Truffle Butter: Large-Scale Manufacturing

Transition from specialty batching to high-volume production. Use a heat-stable, concentrated truffle extract to achieve uniform flavor distribution in every industrial churn—without pooling, weeping, or “truffle pockets.”

Fast SOP

- Standardize Temperature: Temper butter to ~18°C (soft, not melted). Proper plasticity helps the extract bond with fat for uniform distribution (no pooling).

- Measure: Dose at 0.2% — rule of thumb is 2 mL extract per 1 kg butter.

- Dilute (Pre-mix): Blend the measured extract into ~5% of your batch (or a small butter fraction) to create a uniform “carrier,” then add back into the main churn.

- Incorporate: Introduce during the whipping/mixing phase. High shear + correct temperature delivers consistent flavor without aromatic loss.

- Finish + Pack: Move to extrusion/log-forming or tubs. Maintain cold-chain set, then seal for retail-ready stability.

Batch Calculator

Enter butter batch weight (kg). We’ll calculate extract needed at a 0.2% ratio (2 mL/kg).

Retail ready format

Retail ready format

| Butter Batch Size | Extract Required |

|---|---|

| 25 kg | 50 mL |

| 50 kg | 100 mL |

| 100 kg | 200 mL |

5 mL Samples — $19.99

Validate intensity and aroma on a pilot batch before committing to full production. Ideal for R&D, QA validation, and new SKU development.

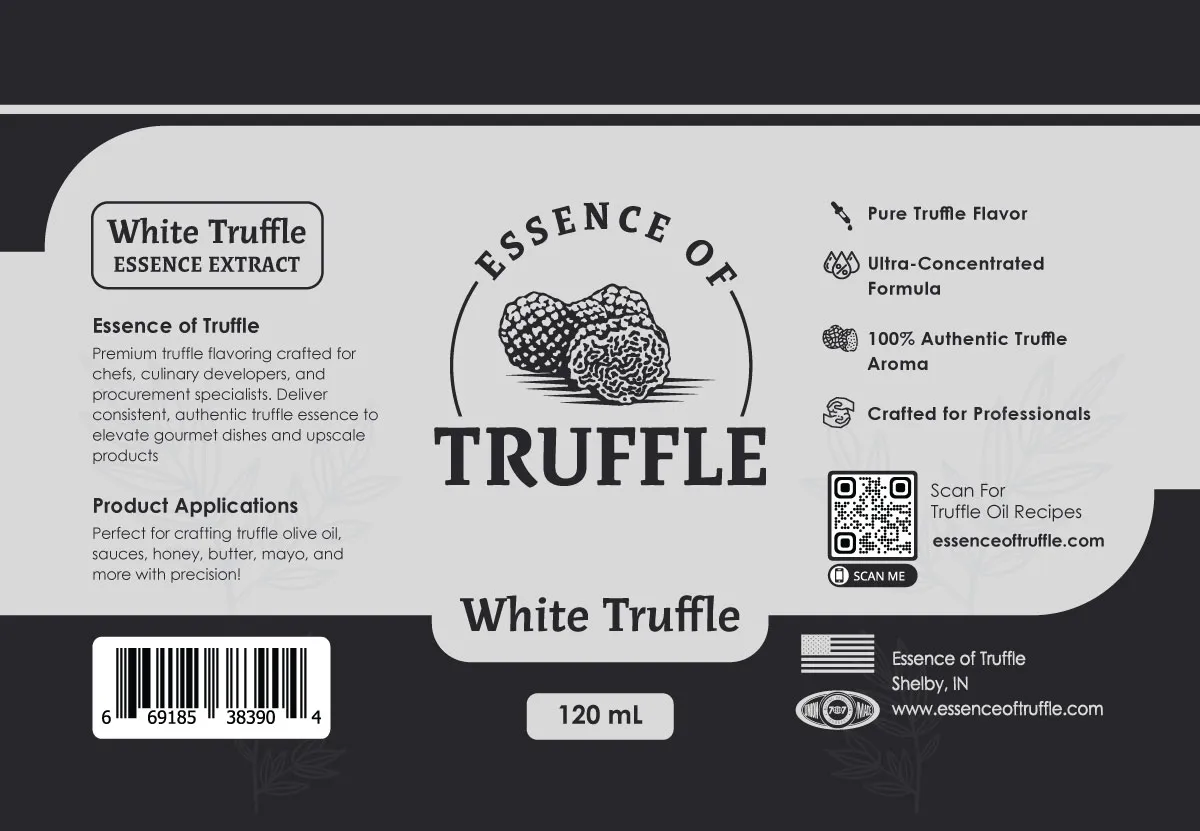

See Essence of Truffle Spec Sheet (PDF)Label & Unique Selling Points

Click the label to expand full screen. Use as a reference for sell sheets, packaging notes, and internal SOP documentation.

Click to Expand

Open Label Asset

Click to Expand

Open Label Asset

Wholesale Sizes for Continuous Production

Running multiple shifts or high-throughput packaging? Larger formats reduce changeovers and keep dosing consistent across vats, tubs, and log-forming lines.

View Wholesale Options See Spec Sheet (PDF)Step-by-Step Truffle Butter Manufacturing Process

Truffle butter succeeds at scale when temperature, mixing energy, and dosing are standardized. A concentrated truffle extract lets you hit the same aroma and flavor target—batch after batch—without relying on variable truffle solids.

1) Temper + Plasticize

Bring butter to a controlled working range (~16–19°C). This preserves structure while allowing uniform incorporation. Avoid melted butter, which can cause separation during set.

2) Dose at 0.2%

Use the baseline ratio of 2 mL extract per 1 kg butter. This provides strong truffle impact while keeping flavor uniform. For new SKUs, validate intensity on a pilot run, then lock the dosing spec for QA.

3) Pre-mix (Carrier Method)

Blend extract into a smaller butter fraction (or ~5% of the batch) to create a uniform carrier, then return to the main churn. This step is the fastest way to eliminate “hot spots” and prevent localized aroma concentration.

4) Incorporate Under High Shear

Introduce during whipping/mixing at stable temperature. The formulation is designed to stay aromatic through industrial shear, helping you achieve uniform flavor without “burn-off.”

5) Optional Visual Flecks

If your market expects a “flecked” look, add 1–2% sterilized truffle break/peelings or a fine mushroom powder in the final 30 seconds of mixing. Add visual solids after the extract is fully incorporated so the fat has already bound the aroma.

6) Pack + Set

Extrude into logs, fill tubs, or portion into foodservice packs. Maintain cold-chain set to stabilize texture and prevent weeping. Consistent dosing and controlled set improves slicability, spreadability, and shelf performance.

Why Essence of Truffle for Large-Scale Butter?

- Standardization: Reduce variance from seasonal truffle inputs and inconsistent solids.

- Cost Control: 0.2% dosing supports aggressive wholesale pricing without sacrificing impact.

- Shelf Stability: Fat-soluble bonding helps prevent separation and maintains consistent sensory outcomes.

Production Gallery

Truffle Butter That Holds Up at Scale

In large-scale butter production, the difference between a novelty product and a repeatable best-seller is process control. A concentrated truffle extract gives you precise dosing, predictable aroma, and uniform flavor—without relying on variable truffle solids that can cause inconsistent intensity.

Use the 0.2% baseline (2 mL/kg), validate intensity with 5 mL samples, then scale confidently using wholesale sizes. When you standardize temperature, pre-mix, and incorporation timing, you get consistent sensory outcomes across vats, shifts, and packaging formats.

Recent Comments